Engine bleed air: a primer

Use of Bleed Air in Aircraft Pneumatic Systems: A Primer

(taken from Chapter 6

on Pneumatic Systems from the 3rd Edition of the book “Aircraft

Systems” by Ian Moir and Allan Seabridge)

The use of aircraft engines as a source of high pressure,

high temperature air can be understood by examining the characteristics of the

turbofan engine. Modern engines “bypass”

a significant portion of the mass flow past the engine and increasingly a small

portion of the mass flow passes through the engine core or gas generation

section. The ratio of bypass air to

engine core air is called the bypass ratio and this can easily exceed 10:1 for

the very latest civil engines; much higher than the 4 or 5:1 ratio for the

previous generation.

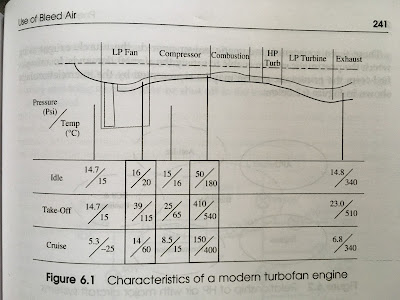

The characteristics of a modern turbofan engine are shown in

figure 6.1. This shows the pressure (in

psi) and the temperature (in degree centigrade) at various points throughout

the engine for three conditions: ground idle, take off power and in the cruise

condition.

It can be seen that in the least stressful condition –

ground idle – the engine is in a state of equilibrium but that even at this low

level the compressor air pressure is 50 psi and the temperature is 180 oC. At take-off conditions the compressed air

soars to 410 psi / 540 oC. In

the cruise condition the compressor air is at 150 psi / 400 oC. The engine is therefore a source of high

pressure and high temperature air that can be “bled” for the engine to perform

various functions around the aircraft.

The fact that there are such considerable variations in air pressure and

temperature for various engine conditions places an imposing control task upon

the pneumatic system. Also the

variations in engine characteristics between similarly rated engines of

different manufacturers poses additional design constraints. Some aircraft such as the Boeing 777 offer

three engine choices, Pratt & Whitney, General Electric and Rolls-Royce,

and each of these engines has to be separately matched to the aircraft systems,

the loads of which may differ as a result of operator specified configurations.

As well as the main aircraft engines the Auxiliary Power

Unit (APU) is also a source of high pressure bleed air. The APU is in itself a small turbojet engine,

designed more from the viewpoint of an energy and power generator than a thrust

provider which is the case for main engines.

The APU is primarily designed to provide electrical and pneumatic power

by a shaft driven generator and compressor.

The APU is therefore able to provide an independent source of electrical

power and compressed air while the aircraft is on the ground, although it can

be used as a backup provider of power while airborne. Some aircraft designs are actively

considering the use of in-flight operable APUs to assist in in-flight engine

re-lighting and to relieve the engines of offtake load in certain areas of the

flight envelope.

It is also usual for the aircraft to be designed to accept

high pressure air from a ground power cart, for aircraft engine starting.

The three sources of pneumatic power provide the muscle or

means by which the pneumatic is able to satisfy the aircraft demands. In a simplified form the pneumatic system may

be represented by the interrelationships shown in figure 6.2 below:

This simplified drawing – the ground air power source is

omitted – shows how the aircraft High Pressure (HP) air sources provide bleed

air which forms the primary source for the three major aircraft air related

systems:

·

Ice protection:

the provision of hot air to provide anti icing of engine nacelles and the wing,

tailplane or fin leading edges; or to dislodge ice that has formed on the

surfaces

·

ECS and

cooling: the provision of the main air source for environmental temperature

control and cooling

·

Pressurization:

the provision of a means by which the aircraft may be pressurized, giving the

crew and passengers a more comfortable operating environment.

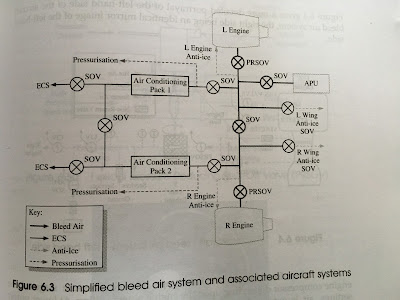

A simplified representation of this relationship is shown in

figure 6.3. This example shows a

twin-engine configuration typical of many business jets and regional jet

transport aircraft.

Bleed air from the engines is passed through a

Pressure-Reducing Shut-Off Valve (PRSOV) which serves the function of

controlling and, when required, shutting off the engine bleed air supply. Air downstream of the PRSOV may be used in a

number of ways:

·

By means of a cross flow Shut-Off Valve (SOV)

the system may supply air to the opposite side of the aircraft during engine

start or if the opposite engine is inoperative for any reason

·

A SOV from the APU may be used to isolate the APU

air supply

·

SOVs provide isolation as appropriate to the

left and right air conditioning packs and pressurization systems

·

Additional SOVs provide the means by which the

supply to left and right wing anti-icing systems may be shut off in the event

that these functions are not required

This is a simplified model of the use of engine bleed air in

pneumatic systems (ATA Chapter 36). A

more comprehensive list of those aircraft systems with which bleed air is

associated are listed as follows with

the accompanying civil ATA chapter classification:

·

Air conditioning (ATA Chapter 21)

·

Cargo compartment heating (ATA Chapter 21)

·

Wing and engine anti-icing (ATA Chapter 30)

·

Engine start (ATA Chapter 80)

·

Thrust reverser (ATA Chapter 78)

·

Hydraulic reservoir pressurization (ATA Chapter 29)

·

Rain repellent nozzles – aircraft windscreen (ATA

Chapter 30)

·

Water tank pressurization and toilet waste (ATA

Chapter 38)

·

Air driven hydraulic pump (ADP) (ATA Chapter 29)

I would like to show some thanks to the writer for rescuing me from this particular predicament. Because of exploring throughout the search engines and seeing opinions which are not productive, I assumed my entire life was over. Being alive minus the solutions to the problems you've resolved by means of this article content is a serious case, and the ones that would have in a negative way affected my career if I hadn't noticed your site. Your actual expertise and kindness in maneuvering every item was invaluable. I don't know what I would've done if I hadn't come upon such a step like this. It's possible to at this moment relish my future. Thanks for your time very much for this high quality and effective help. I won't hesitate to refer your blog post to anyone who requires support about this topic.

ReplyDeletemodern cast iron radiators